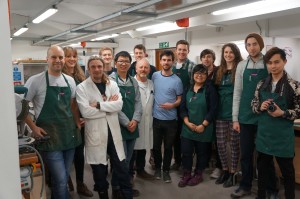

Earlier in the year we hosted a 5th year workshop on the theme of Material Application which was explored through modelmaking. The workshop participants were tasked with two explorations.

Firstly a selection of tools were chosen to be the subject of a scaled up study in cardboard. Outcomes were marked based on their attention to detail and accuracy along. Another big consideration was the cleanliness of the models which, when working with white card proves a surprising challenge.

The results were fantastic giving a great range of interesting objects that demanded a new level of patience and consideration.

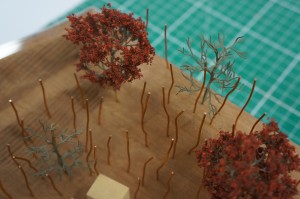

The second task focussed on the University of Manchester campus. Students were asked to choose any building of interest that would allow them to explore different materials and methods of modelmaking.

Methods used included: Wood Turning, Laser cut layering, Silicone Moulding, Resin Casting, Metal Powder Casting, CNC Modelling, Additive Manufacture (3D Printing), Plaster Casting.

The completed models have now been added to this years end of year show display located on the 3rd floor of the Manchester School of Art’s Benzie Building which is open to the public until June 22nd.

This is the first time we have undertaken a workshop brief. Thanks to everyone who took part for all of your hard work and that you enjoyed it as much as we did!