Welcome to all new students and those returning for another academic year!

What’s New at B.15?

- You can find our up to date Health and Safety Document by clicking here – please familiarise yourself with the guidelines written within this document before using the workshop.

- During the summer break several rooms have been rearranged and cleared in the basement to allow us to now occupy a new room to house our model archive and temporary model store in Room B.19. This room can be accessed by asking either of us.

- With the new B.19 model store in place we have been able to rearrange part of our materials store creating space for new machines.

- The main addition to this area is a new spraying area which will shortly be commissioned to allow us to spray model components. As with all new equipment you will be required to ask us to demonstrate the correct practice before using the machine on your own.

- Access to the Photographic Studio can now be made through the materials store thanks to the addition of a new doorway. The old doorway to the studio space is now for staff use only when dealing with material orders.

- We have also taken delivery of a new Flatbed Cutter which will soon be commissioned and located in a re-purposed area of the photographic studio space. This machine will initially be staff operated only until its applications have been clearly established.

- As an upgrade from our previous belt sander/ disk sander combination machine we have now purchased a new and larger belt sander (Also known as a Linisher) which is situated at the back of the workshop next to the bobbin sander. Normal operation and health and safety rule apply when using this machine – as always if you are unsure then please ask for help before using a new machine. This will be up and running next week.

- New Morticing Machine which is used for making squared mortice joints in joinery. This will be particularly useful for 1:1 scale detail models. This is a staff only machine at present but should your project require such a detail we will be on hand to use the machine.

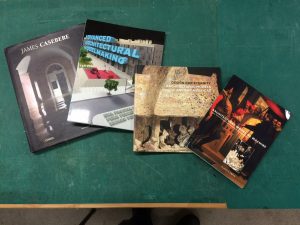

- New Reference Books – We have added four new books to our modelmaking library.

Architectural Model as Machine by Albert C. Smith, 2004 is an in depth historical look at the application of modelmaking in architecture from antiquity to the present day.

Advanced Architectural Modelmaking, 2010 by Eva Pascual I Miro, Pere Pedrero Carbonero, Ricard Pedrero Coderc. This book goes into detail outlining construction methods and provides a good selection of case studies.

Design for Eternity: Architectural Models from the Ancient Americas, 2015 by Joanna Pillsbury, Patricia Joan Sarro, James Doyle, Juliet Wiersema. Published alongside the exhibition of the same name this book provides an interesting look at modelmaking in ancient American history and displays the often overlooked duel function of models as tools and art.

The Spatial Uncanny, 2001 by James Casebere. The artwork of James Casebere demonstrates the amazing perspective images that can be achieved through photographing interior models.

- We have a new restructured and re-branded permanent exhibition space on the first floor here at Humanities Bridgford Street; B.15 ARCHITYPES. The exhibition gives a categorised breakdown of model types and features a wide range of applications in the context of projects you may have to produce during your time here as students and beyond. Please get yourself over to have a good look around pick up a free new guidebook whilst they last!

- Lastly we are now on social media Instagram and Twitter where we will be sharing work and events @b15workshop

See you all soon!

Scott & Jim